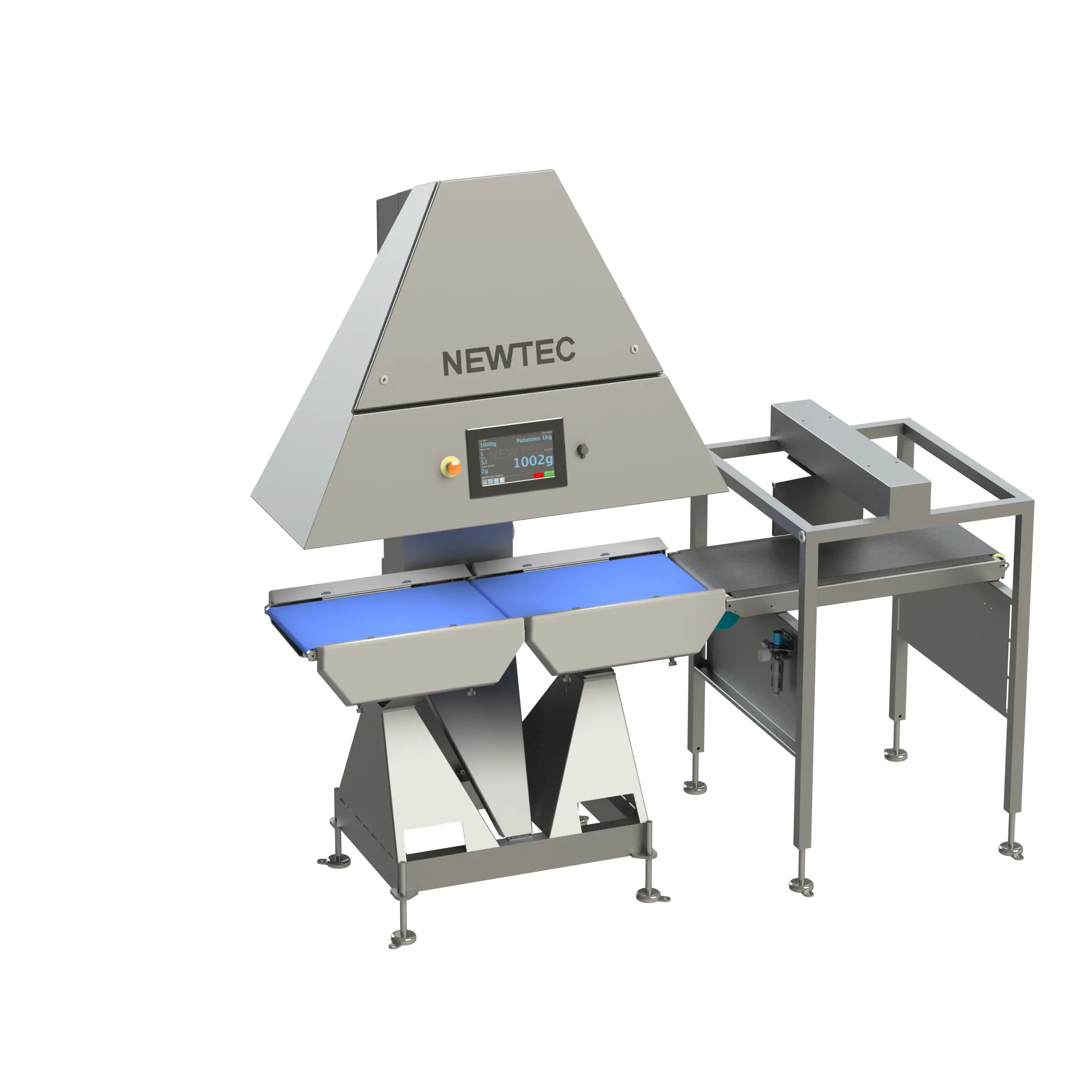

Weight control with integrated visual inspection

QC90-2 CR-LR Checkpoint series

Advantages

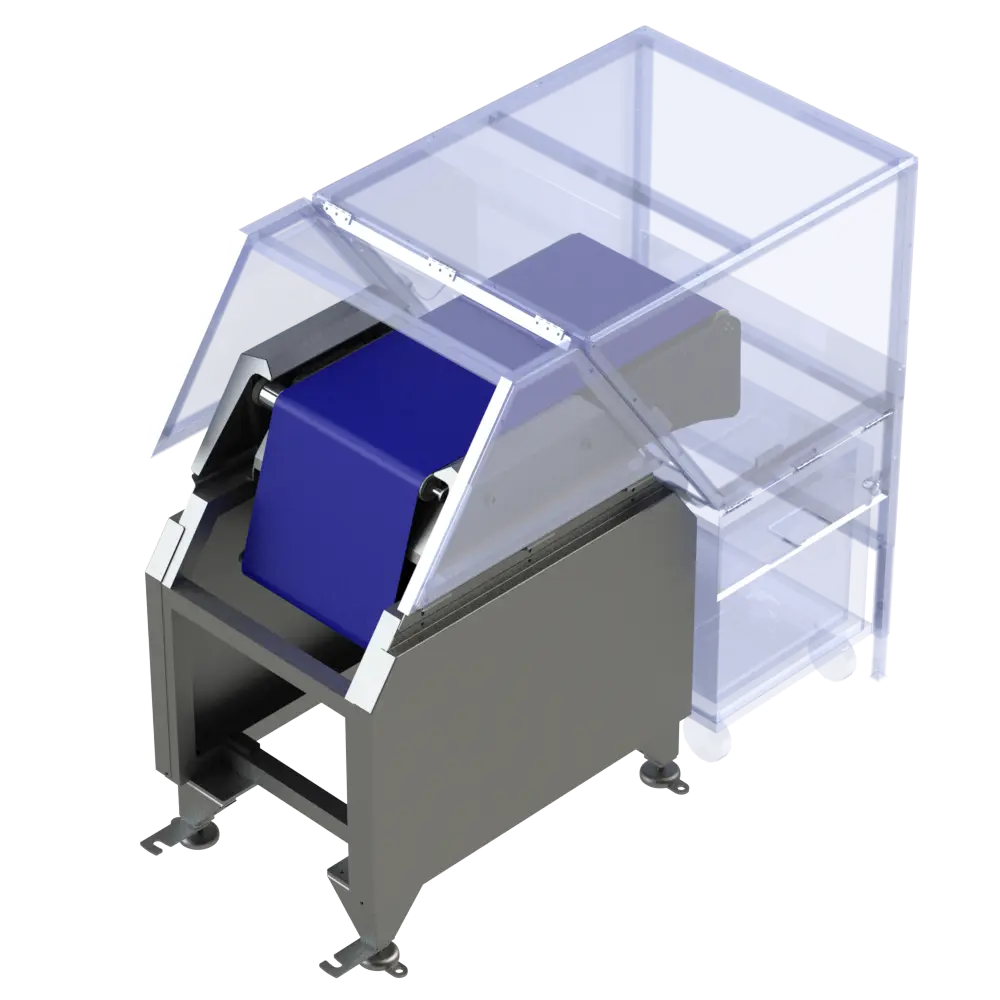

- In-line Checkweigher with high accuracy

- Up to 90 units per min.

- Vision control for loose product detection and product separation

- Container validation (form, size, colour, orientation)

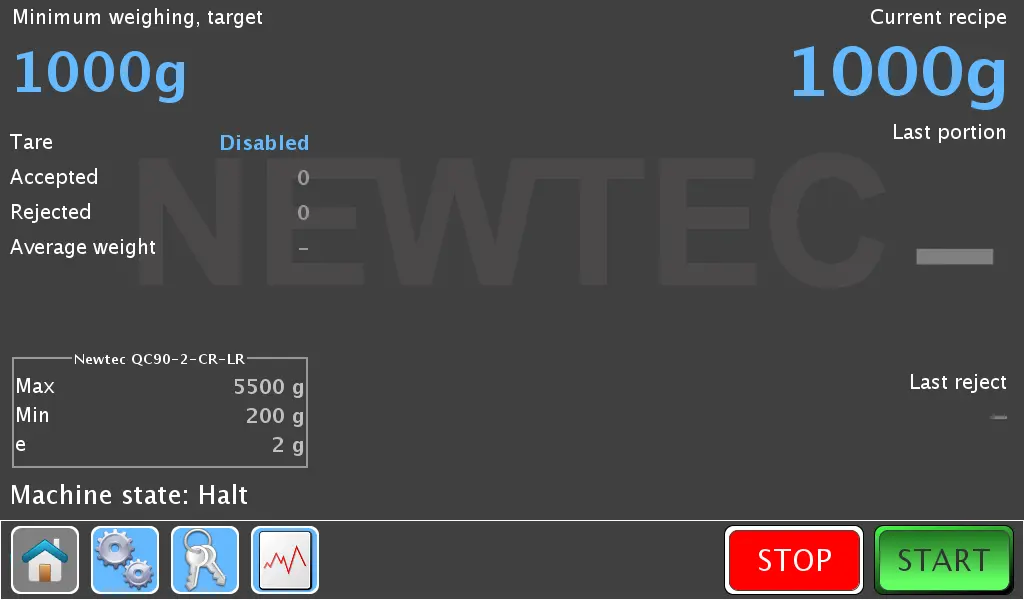

- Minimum- and ℮-weighing mode

- WebServices available for remote servicing and for capturing production data. Read more

- MachineLink enabled - from only one touchscreen, either on our checkweigher or our weighing machine, recipe change and start/stop for both machines is possible

Application

Products in bags, punnets, trays and similar packaging

Your advantages

- Combined checkweighing and visual inspection

- Visual quality control

- Product leakage detection

- Flexible selection of rejectors

- Extremely durable and accurate load cell

Designed according to OIML R51 and approved according to the European Measurement Instruments Directive (MID).

| MID Accuracy Class: | XIII(1) |

|---|---|

| ℮ | 2 g |

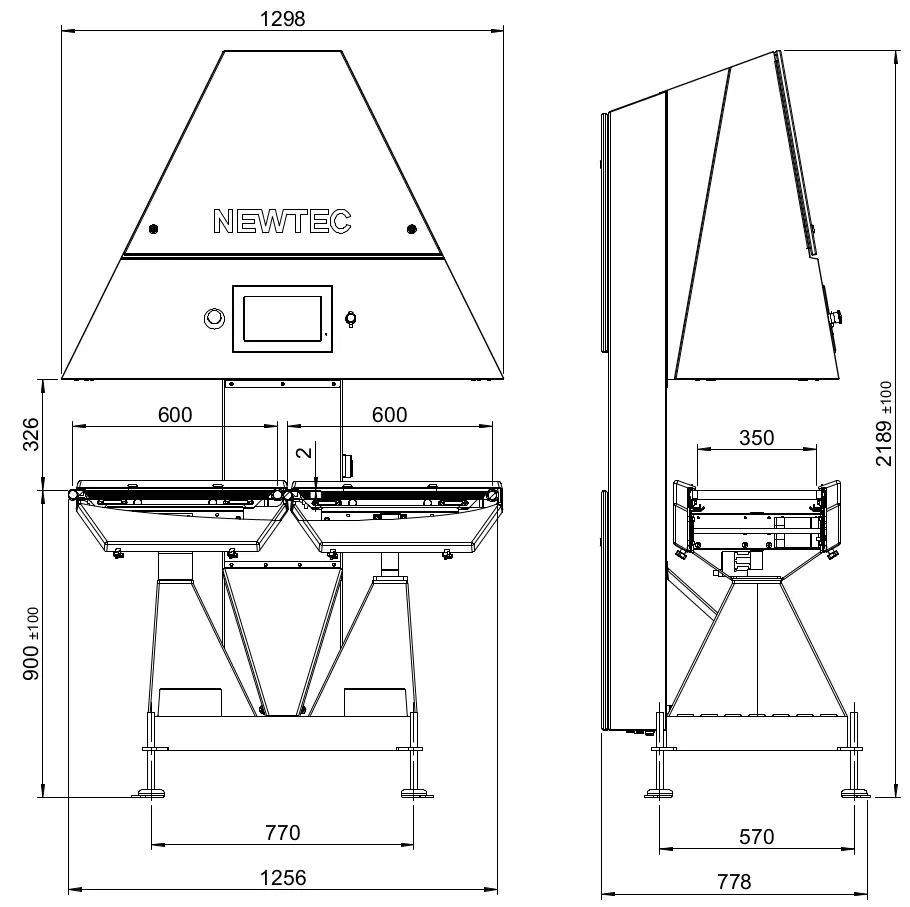

Weight and dimensions of applicable packagings

| Max. weight: | 5500 g |

|---|---|

| Min. weight: | 200 g |

| Max. Product length: | 450 mm |

| Max. Product width: | 350 mm |

| Max. Product height: | 100 mm |

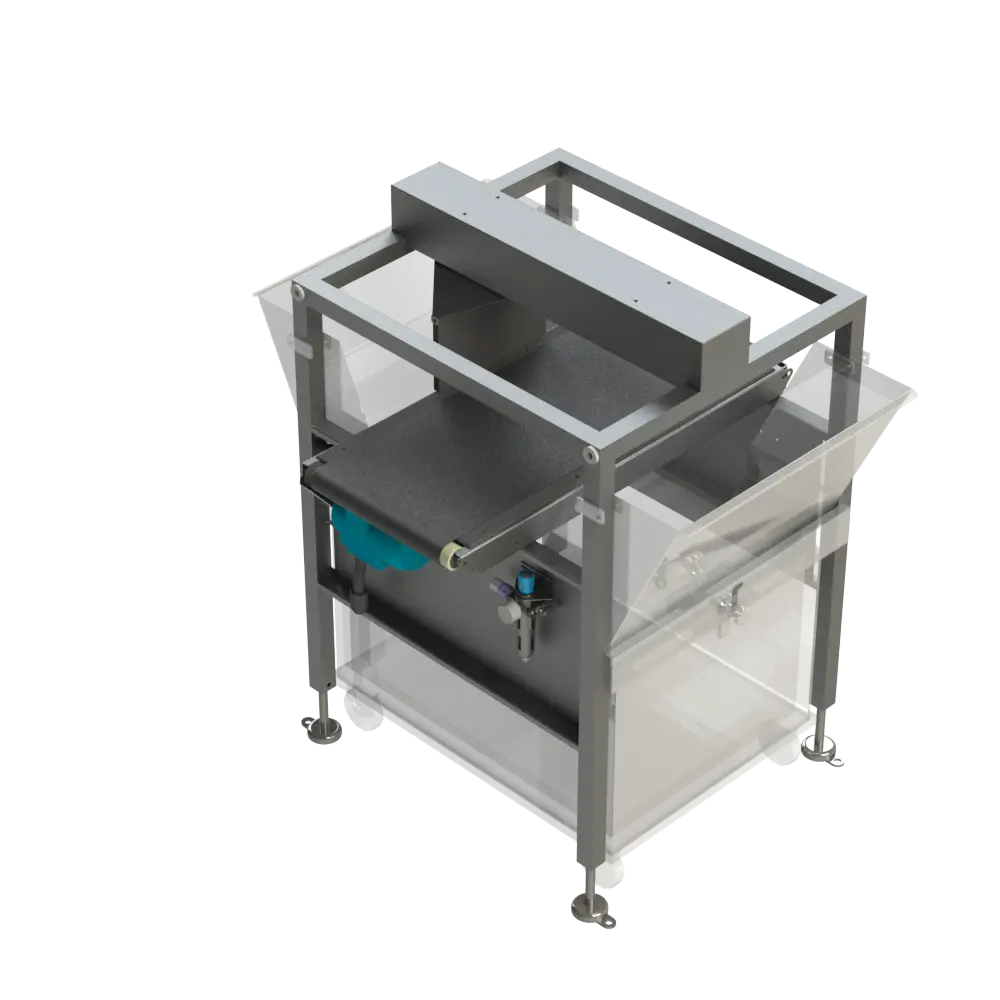

Configuration Options

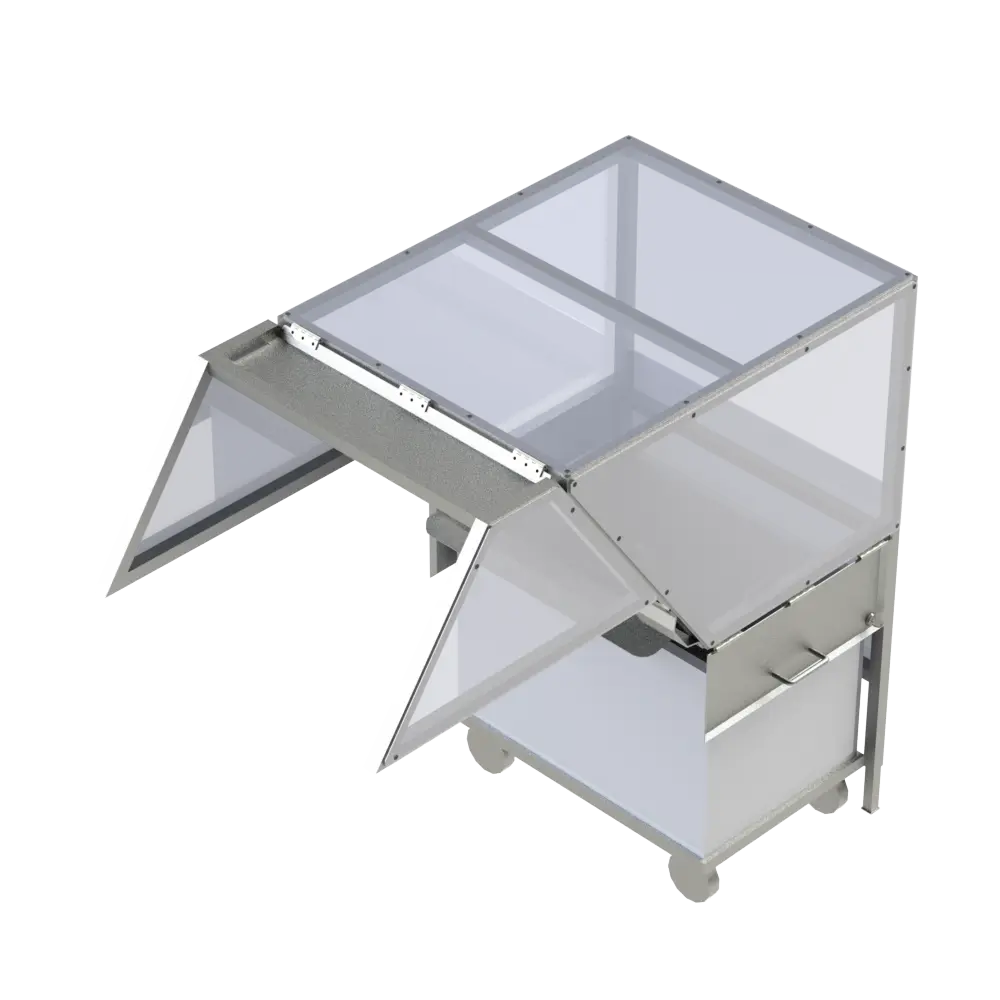

Cross reject (CR). Standard

Extra cross reject

Dropdown reject (DR). Optional

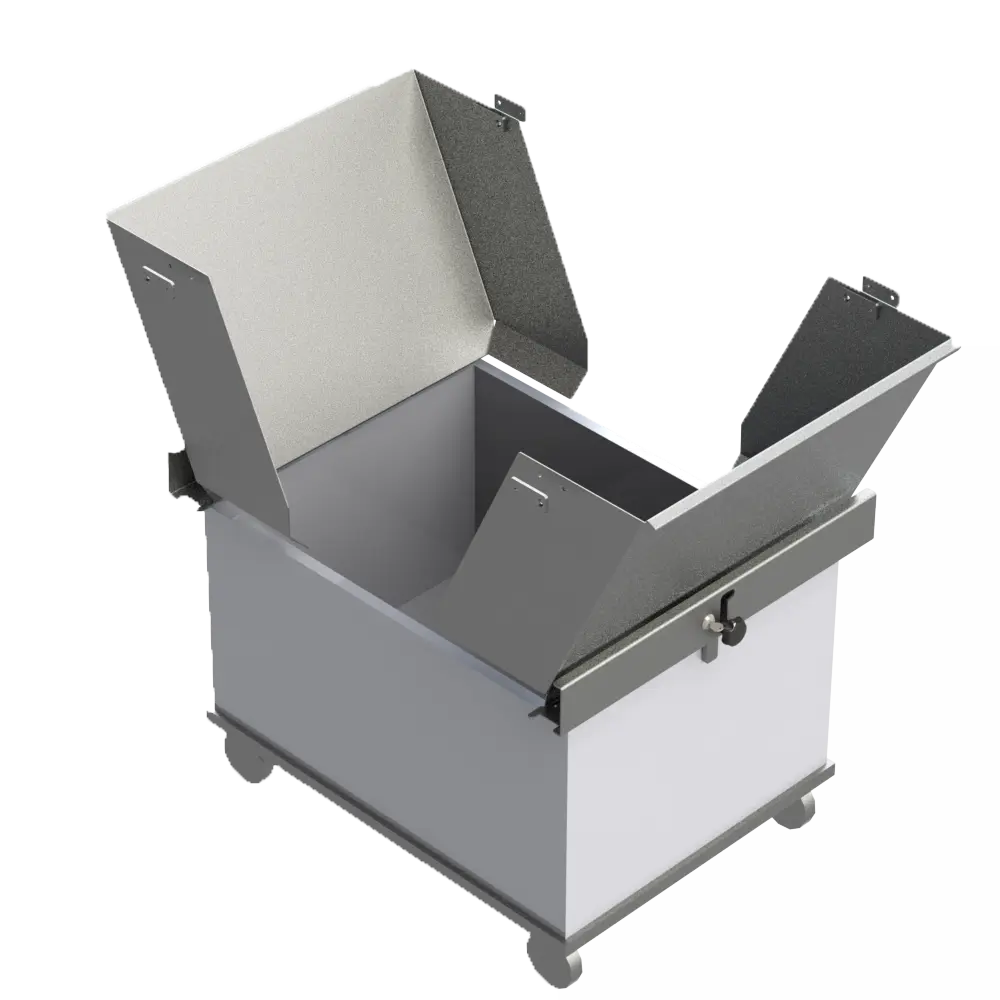

Lockable bin, cross reject (extra)

Lockable bin, drop down reject (extra)

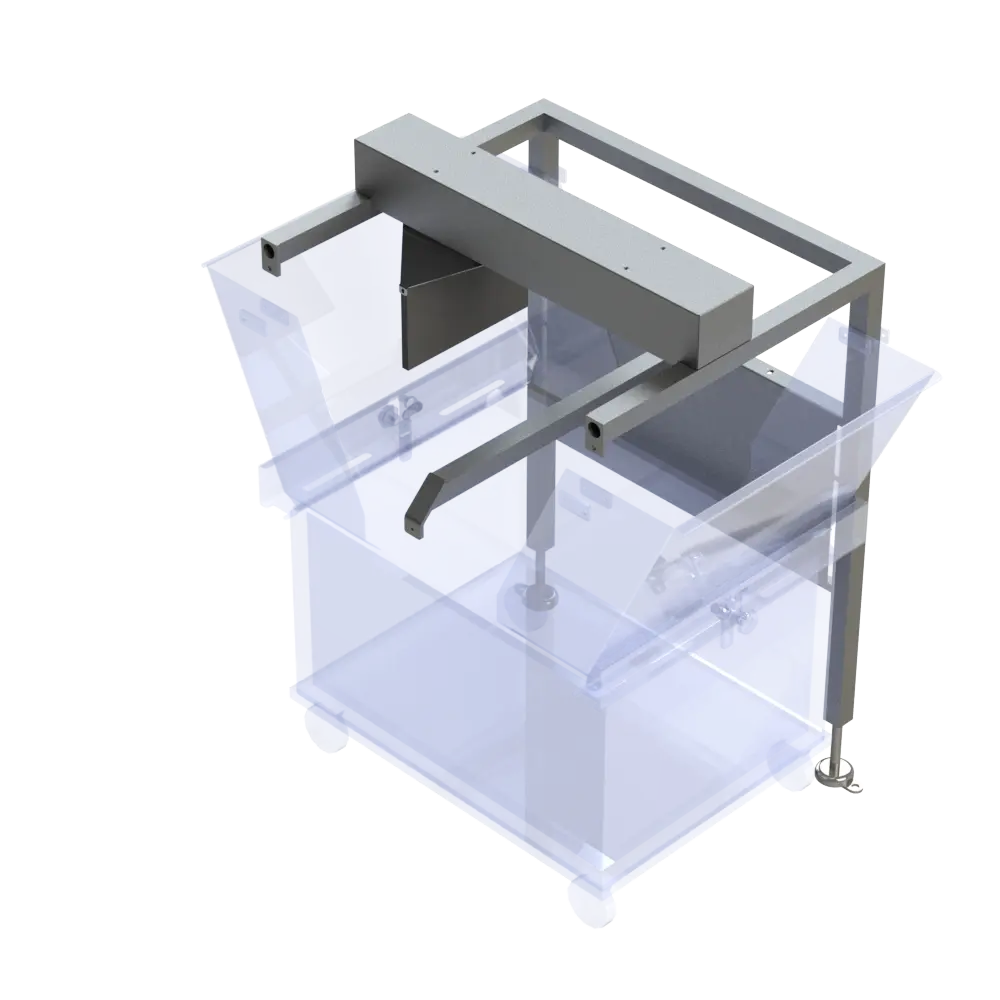

Catch arm reject (AR). Optional

| Capacity: | Up to 90 packs per min. |

|---|---|

| Material: | According to EU rules on food contact materials. |

| Air Requirement | |

| Connection: | 3/8" |

| Min. pressure: | 6 bar (0.6 MPA) |

| Consumption: | 50 NL/min. |

| Electrical Requirement: | 3x230 VAC or 3x400 VAC (N) PE 50/60 Hz 3 kW |

| Environment: | 5º C - 35º C |

| Weight: | Up to 295 kg |

Newtec Software

- Intuitive user interface

- Informative and upgradable

- Same user interface on all Newtec weighing and packaging machines

Contact

Please contact your local representative for more information. See more