Sorting potatoes simultaneously by quality, size, and shape

How can our optical sorting machine for potatoes optimise your production?

Newtec's optical sorting machine for potatoes, model Celox-P-DUAL-UHD, is designed to sort potatoes by size, shape and quality in a single-stage process. The machine sorts washed potatoes directly, eliminating the need for pre-grading and minimising the need for manual labor, whilst ensuring consistent quality and high throughput.

Up to 16 categories of products can be sorted out simultaneously. Sorting criteria for these categories are instantly customisable according to the current needs. Premium product selections can effortlessly be sorted out of bulk produce.

Being completely configurable by the operator or factory manager the sorting machine permits near-instant turn-around time and unparalleled flexibility. Additionally the machine collects detailed real-time product data which is available with Newtec WebServices. The same data can optionally be integrated in your own business IT-systems for further analysis.

Your advantages

- Quality, size and shape sorting in one machine

- Accurate selection of high-value products

- Consistent quality output

- No need for mechanical pre-grading

- Gentle product handling

- Robust stainless steel construction

- Modular design for future extension (up to 16 categories/outlets)

- WebServices , our data collection system, enables capturing of complete product information and remote servicing.

Capacity

Celox-P-DUAL-UHD for potatoes: Up to 30 tonnes of product/h. depending on the size of the potatoes. Choose between 4, 8 and 12 lanes depending on required capacity.

- What is the most challenging aspect of sorting potatoes and how do you overcome this issue in your equipment?

- What are the main benefits associated with using Newtec's optical sorter when sorting potatoes?

- How does artificial intelligence (AI) enhance operations in Newtec's optical sorter?

- What technology do your optical sorters use to obtain a 360° scan of each potato?

- What role do optical sorters play during the processing of potatoes related to food waste/sustainability?

- Read more

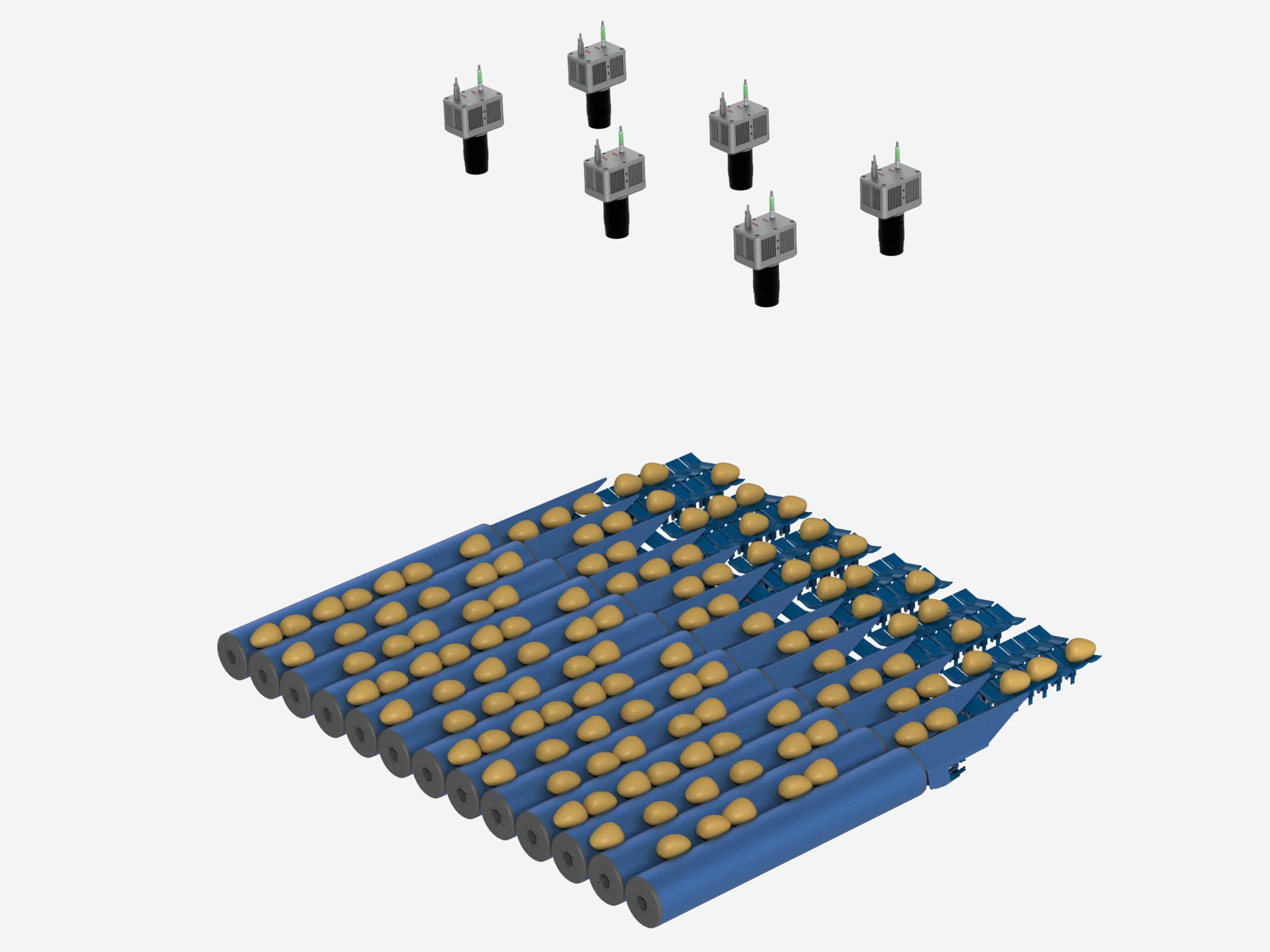

Infeed section

The infeed section receives products and conveys them into the camera section. Advanced computer control ensures optimum throughput on all lanes.

Camera section

In the camera section each product is inspected to capture accurate data on size, shape and surface quality. Each product is evaluated according to the grading parameters chosen by the operator.

Spinaflex™ section

Products enter the Spinaflex™ section after passing through the camera section. The Spinaflex™ belt directs each product to the correct outlet, ensuring product integrity with minimal drop heights.

360-Degree Scan of Every Potato

Every potato undergoes a thorough assessment upon entering the camera section of our potato sorting machine. The extended camera section in the Celox-P-DUAL-UHD model is equipped with six cameras that capture 360-degree images of each potato up to 45 times, providing precise data on size, shape, and surface quality.

The potatoes are guided through the camera section on vibrating rollers—a unique, patented system that ensures each potato is inspected from all angles as it rotates and moves forward, propelled gently by roller vibrations.

Our machine is designed for maximum efficiency, combining high production output with a compact footprint.

We’re proud to offer an efficient, space-saving machine that provides comprehensive quality checks and precise classification of each crop before it reaches sales packaging. We look forward to helping you maximize the value of every potato by sorting them in the most profitable way for your business. We look forward to optimising the value of each of your potatoes by sorting them in the most profitable way.

Complete surface coverage

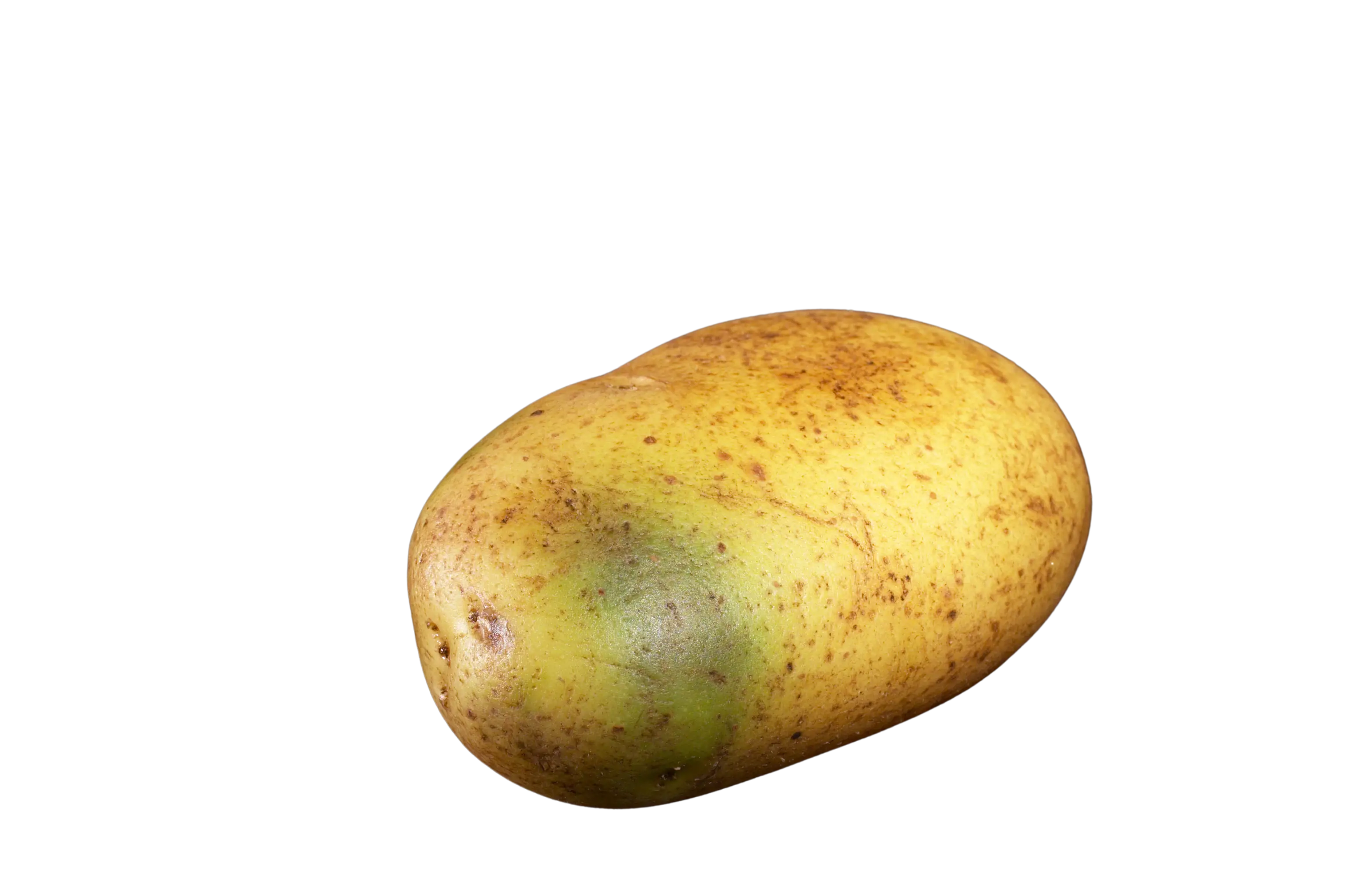

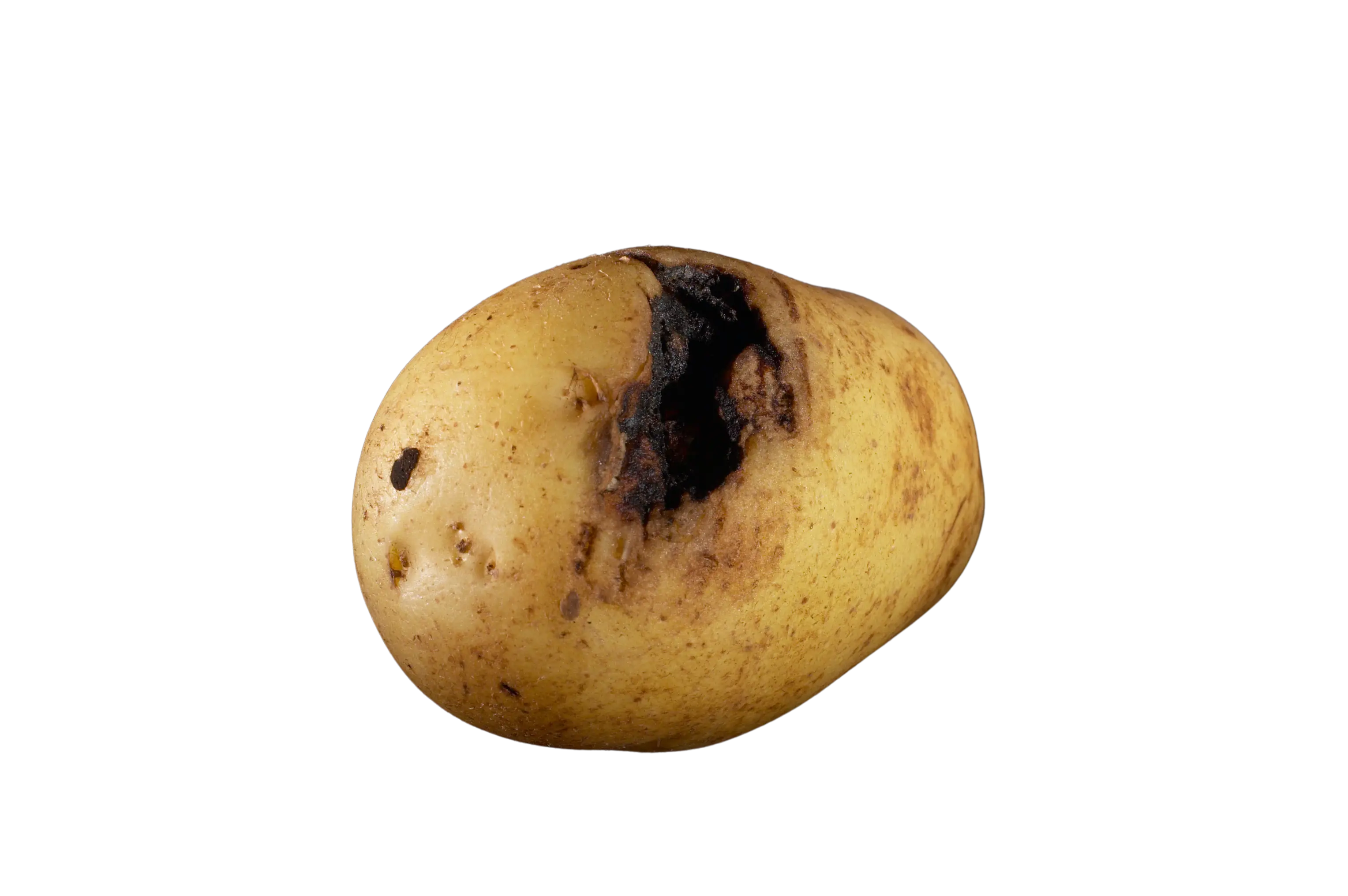

Our in-house developed high speed camera checks for a wide range of surface defects such as:

Classification of every single potato before it is presented in the sales packaging.

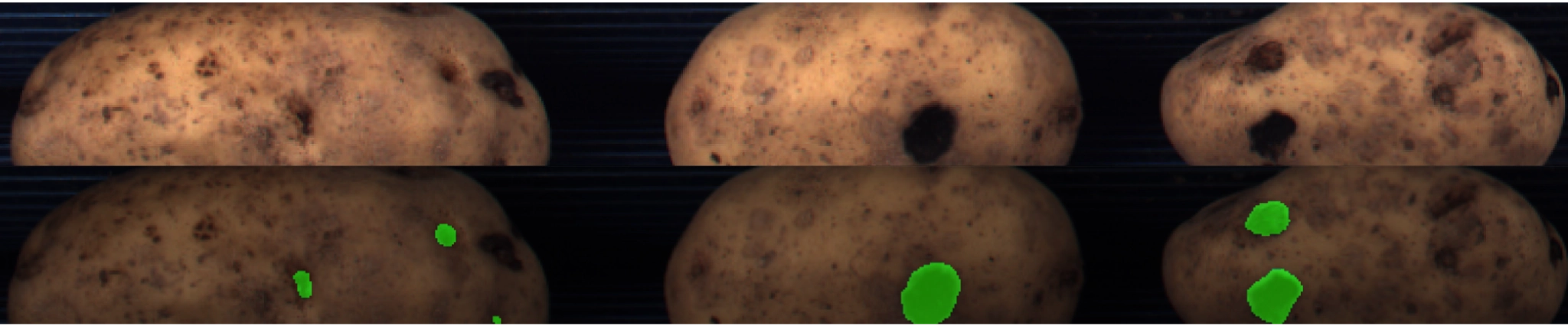

Spotting the Difference: Wormholes or Rhizoctonia in Potatoes

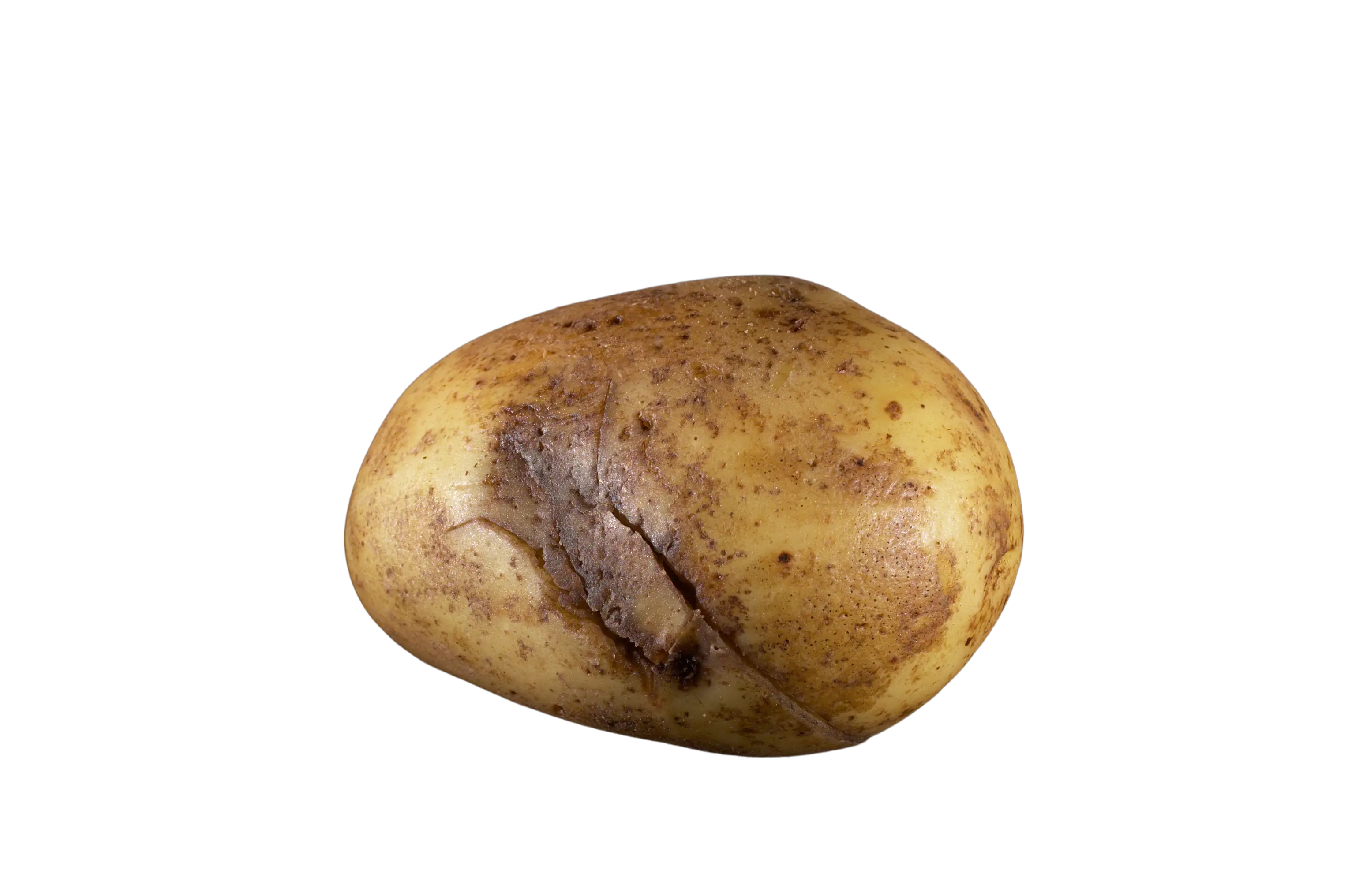

Our optical sorting machine for potatoes is able to distinguish between potatoes affected by the fungus Rhizoctonia and those with wormholes. The visible black spots are nearly impossible to detect with the human eye, but with our advanced AI chip, our cameras can accurately separate the two, ensuring that potatoes with wormholes are discarded.

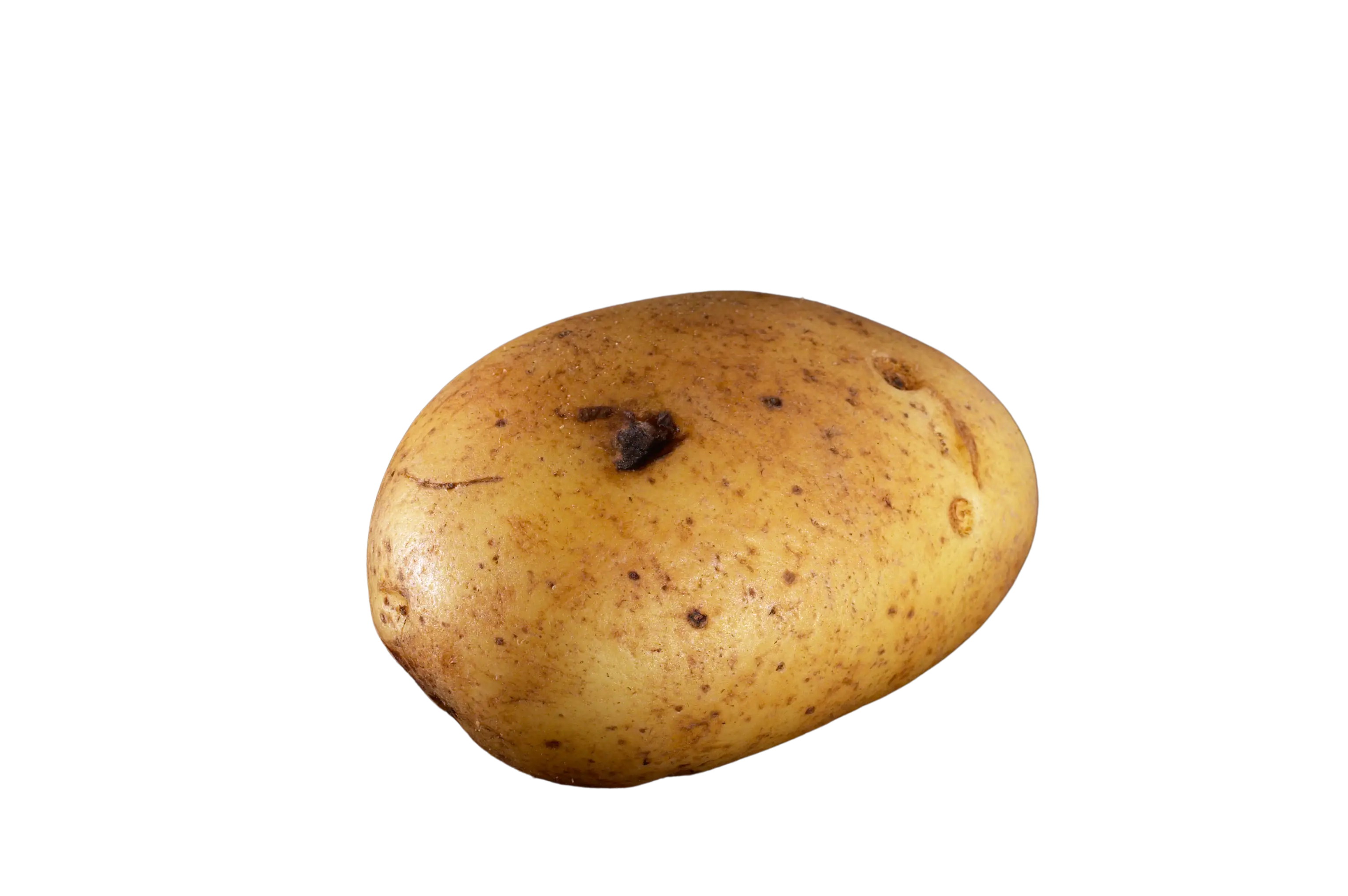

Potatoes with the Rhizoctonia fungus detected by the camera

Potatoes with wormholes detected by the camera

We have used Newtec machines for over 30 years.

We are talking about machines with unusually high precision that virtually never break. In addition, it is easy to get hold of spare parts. When we call, Newtec will be here within short time and they stay until the machines run. It is really nice to deal with.

Professional decency all the way

Peter Anker, CEO and owner, Storøhage Kartofler A/S, Denmark

It is astonishing how many criteria growers, manufacturers and consumers have when it comes to defining the best potato quality. There is the growers' demand for disease resistance, agronomic qualities and profitability as well as manufacturers' demands for high-speed production, accuracy and consistency in quality. The large supermarket chains have on-going demands for better and more competitive products to offer their consumers in the different markets. Wishes for appearance, variety, taste, size, shape and quality varies from consumer to consumer, market to market.

Quality control begins prior to the crop being planted. The growers choose the most suitable fields for growing crops, agree on a fertilising strategy and determine the planting density for the different varieties in order to optimise the yield.

The production manager inspects the fields during the growth season to check for vira, bacterial diseases, areas with water shortage or other conditions of importance for the quality.

When the potatoes have been harvested and stored, a sample of the raw material from the lot is taken. The sample is analysed and the suitability of the lot is evaluated for export.

Newtec manufactures the machines for the type of potato that will work in your market and live up to your quality standards and pre-set classifications.

We look forward to optimising the value of each of your potatoes by sorting them in the most profitable way.

Read about our optical sorting machine for carrots.

Contact

Please contact your local representative for more information. See more