Popular weighing machines

Our portfolio

Regardless of product or packaging, portion size and capacity, we have your upgradeable solution.

Newtec provides the highest quality assurance in the industry and is servicing a broad range of customers from small family packaging houses to the largest industrial factories in the world.

We offer multihead weighing machines for:

- fresh and processed food

- washed and unwashed crops

- fragile and less fragile crops

- product sizes from grains to grapefruits

- and within portion sizes from 170 g up to 25 kg

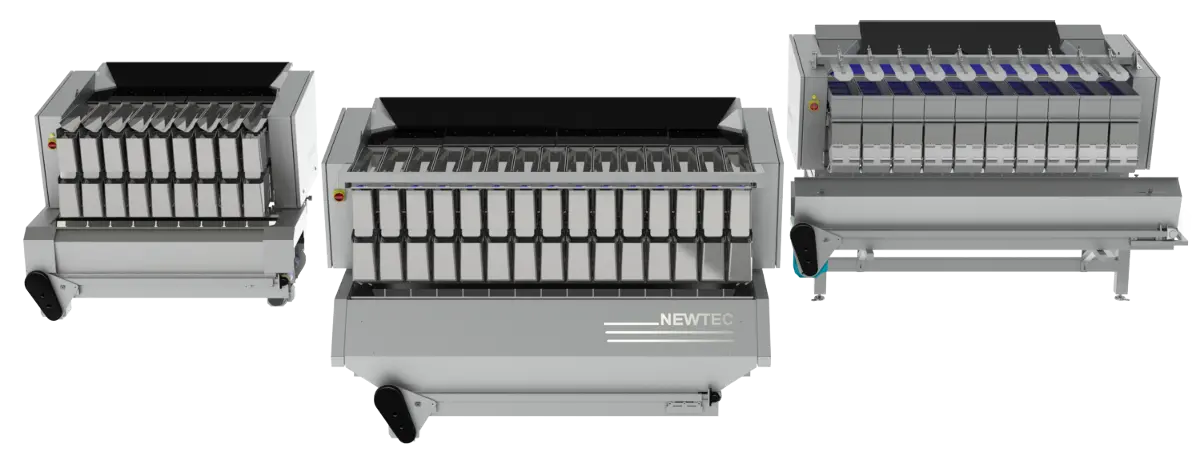

Limitless options and features

Newtec's wide and flexible range of weighing machines opens up several innovative and customised solutions that meet the needs of packhouses and the packaging industry and the requirements they set. Our cost-effective solutions offer a number of advantages such as high weighing accuracy, flexibility, quality and production optimisation.

We meet the needs of the smallest and largest packaging houses with our multihead weighing machines with 4-9 weigh heads and 14-15 weigh heads, running up to 140 portions/min.

Your advantages

- Accurate and gentle handling at high speeds

- Low cost per portion

- Optimum running, also when the products are fed irregularly into the weigher

- Easy access for cleaning and service

- User-friendly touch panel

Machine approvals

Our multihead weighing machines have been approved according to the European Measurement Instruments Directive , MID/OIML R61*.

Material: According to the EU/FDA rules on food contact materials.

The following configurations are primarily for:

Why choose Newtec weighing machines?

25,000 installations worldwide In the last four decades represented through 50 dealers

Durable stainless steel construction ensures longevity and reliablity in tough environments

Integration into existing lines ensures a perfect fit for your production

Optimise your production through high speed machines that incorporates the newest technology

Weighing machines for fresh and processed food:

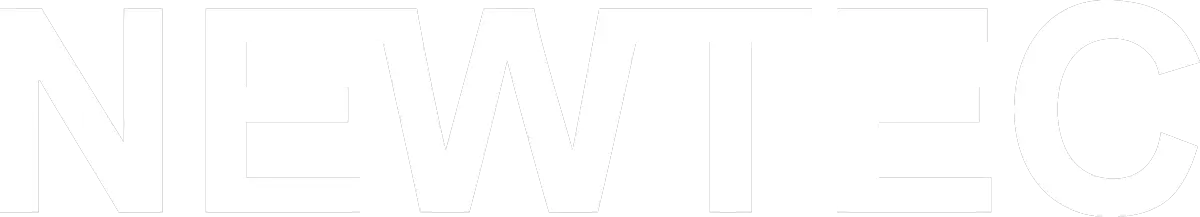

Weighing machine for extremely large products

Setting international standards

Our multihead weighing machines are well known for a very high level of accuracy, efficiency and extraordinary gentle handling of products. All are key factors when designing Newtec machines and the stainless steel construction and excellent mechanical design-make them extremely durable.

Let us be a key partner in optimising your production.

Contact

Please contact your local representative for more information. See more